أرسل لنا رسالة

copper grinding ball mill

Copper Ore Grinding Ball Mill Alibaba

So order a new copper ore grinding ball mill and make ore separation simple. Related Searches: gold copper ore grinding machinery paracord 9 strand wholesale periarthritis

machine grinding of copper wet type ball mill FOUR CINQ

grinding ball mill copper ore ball mill machineINUSTI. Working Principle of the Gold Iron Copper Ore Stone Grinding Ball Mill Machine: The ball mill made by the Chinese ball grinder

copper mining process ball mill fourcinq.au

The 24 x 39.5 Ball Mill The Copper Mountain ball mills are 7315 mm [24 feet] in diameter and 12040 mm [39.5 feet] long. They are overflow discharge ball mills with inside diameters of

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is

Ball Mill Prominer (Shanghai) Mining Technology Co.,Ltd.

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field,

Copper Ore Crushing, Grinding & Flotation

21/5/2017· Operation of crushing plants, rod mills and ball mills is understood by many, and most operators are comfortable with the use of this type of equipment which has been around for

Ball Mills Industry Grinder for Mineral Processing JXSC

【Ball Mill Working Principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the

Ball Mills Mineral Processing & Metallurgy

13/2/2017· Grinding (Rod) or (Ball) Mill TYPE D Has single weld, triple flanged, construction which means the shell is furnished in two sections, flanged and bolted in the center. All flanges

Ball Mills and Ball Charging Bulk Handling Technologies

Grinding is the process of achieving particle size reduction through attrition and compressive forces at the granular level. The grinding media in a ball mill is typically steel or ceramic balls

Ball Mill an overview ScienceDirect Topics

William G. Davenport, in Extractive Metallurgy of Copper (Fifth Edition), 2011. 3.5.2.2 Ball Mills. The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

Ball mill, also known as ball grinding machine, is a well-known ore grinding machine, is widely used in mining, construction, aggregate application. JXSC start the ball mill business in 1985, supply globally service includes design, manufacturing, installation, and free operation training. 【 Type 】 According to the discharge type, overflow

Grinding Mill NoakMech

31/8/2021· A ball mill is a reguler tipe of grinding mill. It has a horizontal, slightly inclined silinder filled with balls of metal or stone. These balls grind materials by impact and friction with the rolling balls. Ball mills have longer length and small diameter, and have a length between 1.5 and 2.5 times its diameter.

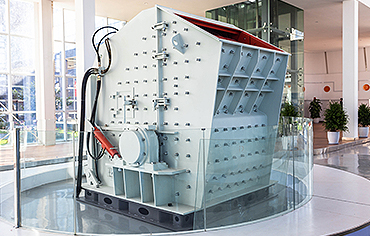

Paper # 25 Copper Mountain Overview on the Grinding Mills

The Copper Mountain ball mills are 7315 mm [24 feet] in diameter and 12040 mm [39.5 feet] long. They are overflow discharge ball mills with inside diameters of 7315 mm [24 feet] and grinding lengths of 11887 mm [39 feet]. Each Ball mill is also driven by two 8,500 horsepower ABB motors. Figure 3 The 24’ x 39.5’ ball mill

Flexible milling and grinding solutions that last

Our ATOX® coal mill has large rollers with great grinding capability of all types of coal, tolerating moisture levels up to 20 percent. For the mining industry, our semi-autogenous (SAG) grinding mill uses a minimal ball charge in the range of 6-15 percent. It is primarily used in the gold, copper and platinum industries as well as in the lead

Mill (grinding) Wikipedia

SAG mills are primarily used at gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industries. Tower mill . Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process. Like ball mills,

What’s the Difference Between SAG Mill and Ball Mill

26/11/2019· The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s

case study of ball mill grinding copper

Laboratory Grinding Mill Ball & Rod . Översätt den här sidan. Here is a convertible laboratory ore grinding mill. Use it as a Lab Ball Mill if you like over-grinding or a Rod Mill if you prefer selective milling. Sizes 8″ x 8″ to 8″ x 16″ (ball and rod) Extra Large Batch 12" x 15" (10 kilo ore load) Mild steel construction

Dealing With Scat in Mill Processing PumpEng Submersible

In a mining plant or processing mill, they have a big grinding circuit for crushing raw material, these are usually Ball or SAG mills. Inside these Sag/Ball mill are big steel balls that grind ore via an impact process. In simple terms, these hard metal steel balls get to the top of the rotating chamber and fall down crushing the ore being

Difference Between Sag Mill vs Ball Mill mech4study

12/10/2017· 1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is used to grind the pieces of raw material into. powder-like structures. 3.

Sturdy And High-Quality copper ball mill Alibaba,com

China Factory Price Energy-Saving Copper Ore Grinding Plant Steel Ball Mill / Set. 1.0 Sets (Min. Order) CN Henan Hongji Mining Machinery Co., Ltd. 10 YRS. 5.0 (6) "professional supplier" Contact Supplier. 1/6. Mn60 solid cast steel ball for copper ball mill grinding. $965.00 / Ton. 3 Tons (Min. Order) CN Henan Nestor Mechinery Co., Ltd. 1 YRS. Contact Supplier.

Ball Mills Industry Grinder for Mineral Processing JXSC Machine

Ball mill, also known as ball grinding machine, is a well-known ore grinding machine, is widely used in mining, construction, aggregate application. JXSC start the ball mill business in 1985, supply globally service includes design, manufacturing, installation, and free operation training. 【 Type 】 According to the discharge type, overflow

Ball Mill Explained saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be

Ball Mill for Sale Mining and Cement Milling Equipment

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher, flotation machine, concentrator, filter press. Auxiliary equipment: Linear vibration screen, cyclone.

Small Ball Mill Mini Ball Mill for Small Scale Mineral Grinding

Small Ball Mill. Feeding size: ≤25mm. Capacity: 0.65-25t/h. Motor power: 18.5-380kW. Applications: It can be used in production industries such as cement, refractory materials, fertilizers, ferrous and non-ferrous metal beneficiation and glass ceramics, as well as schools, scientific research units and laboratories.

Buy Ore Ball Mill for Mineral Processing Iron & Gold Ore Ball Mill

Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal ore. The core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials

(PDF) Analysis of process of grinding efficiency in ball and rod mills

26/9/2018· The article concerns issues related to the copper ore ball mill grinding process, operating at different technological parameters. The aim of the study was to investigate the influence of various

What’s the Difference Between SAG Mill and Ball Mill

26/11/2019· The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s

Dealing With Scat in Mill Processing PumpEng Submersible

In a mining plant or processing mill, they have a big grinding circuit for crushing raw material, these are usually Ball or SAG mills. Inside these Sag/Ball mill are big steel balls that grind ore via an impact process. In simple terms, these hard metal steel balls get to the top of the rotating chamber and fall down crushing the ore being

case study of ball mill grinding copper

Laboratory Grinding Mill Ball & Rod . Översätt den här sidan. Here is a convertible laboratory ore grinding mill. Use it as a Lab Ball Mill if you like over-grinding or a Rod Mill if you prefer selective milling. Sizes 8″ x 8″ to 8″ x 16″ (ball and rod) Extra Large Batch 12" x 15" (10 kilo ore load) Mild steel construction