أرسل لنا رسالة

design of jaw crusher

Jaw Crusher Liner Plate Design & Profile Shapes

根据热度为您推荐•反馈Jaw Crusher an overview ScienceDirect Topics

Jaw Crusher Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time Crushers. Jaw crushers are heavy-duty machines

Jaw Crusher Explained saVRee

Jaw Crusher Components. The main components of a typical jaw crusher are: Fixed Jaw; Moving Jaw; Jaw Liners; Main Shaft (Pitman Assembly) Drive Pulley & Flywheel; Toggle Plate(s) &

Jaw Crusher ScienceDirect

1/1/2016· The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact. 4.2. Design of Jaw Crushers. Jaw crushers are designed to

Characteristics and Comparison of Four Types of Jaw

28/10/2021· There are two jaws in a blake jaw crusher, one is stationary and vertical, the other is movable and swing. The swing jaw reciprocates in a horizontal plane, and generally the

What is a Jaw Crusher? MEKA Crushing Equipment

In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported by a toggle plate at the

How Does a Jaw Crusher Work Jaw Crusher Kemper

Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit. Types of Jaw Crushers. Jaw

What Are Jaw Crushers and How Do They Work? Oreflow

28/3/2019· In single-toggle jaw crushers, the moving crusher operates in an elliptical pattern while in double-toggle jaw crushers, a pendulum motion is utilized in order to crush hard materials. The crushing force is generated by

International Journal of Mechanical Engineering Improvement of

Fig.3 shows the configuration of the jaw crusher and geometrical and operation parameters are given in Table 1. Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and

Primary Crusher Selection & Design Mineral Processing

23/12/2015· Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs. The selection of the primary crusher must consider best-in-breed maintenance services as the whole mine’s production

Jaw Crushers McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material. A toggle plate and tension rods

Jaw Crushers MEKA Crushing & Screening Plants

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to

Jaw Crusher Eastman Rock Crusher

1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Jaw crusher SlideShare

14/11/2015· Figure 1 Jaw Crusher Design of Jaw Crusher As jaw crusher is designed to impart an impact on the solid particles placed between a fixed and a moving plate. The faces of the plate is made up of harden steel, both plates

How Does a Jaw Crusher Work Jaw Crusher

Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake), have long been the standard used for crushing hard and abrasive rocks, as well as

What Are Jaw Crushers and How Do They Work?

28/3/2019· March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who

International Journal of Mechanical Engineering Improvement of Jaw

Improvement of Jaw Crusher Design by DEM & FEA Approach Ömer AKIN,1 Metin MUMCU,2 and Yaghmur ABILOV3 1,2,3MEKA Beton Santralleri A Ş Abstract Jaw Crushers are used as primary crusher at quarries, mines, and concrete recycling operations. Rocks, Rubbles and Slags are broken into small particles in jaw crusher under the high pressure exerted by moving and

The story of C Series jaw crushers where it all began?

16/6/2020· The original design of C Series jaw crusher is still in use. Over the years, the C Series jaw crushers have received multiple improvements and optimization. For example; developments in the 3D design capabilities have enabled FEM (Finite Element Method) calculations, as well as digitalized signal processing and mathematics has made crushing

Jaw Crushers JW Series

Jaw Crushers The JW Series is engineered for portability and ease of use. The rugged design delivers the reliability you can expect from Cedarapids. They feature a hydraulically actuated wedge system that allows variable closed side-setting adjustments to be made quickly and easily. Designed to suit track, mobile or static plant installations, these durable crushers utilize heavy

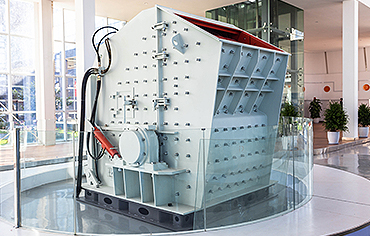

(PDF) Design of Impact stone crusher machine

31/5/2019· Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher and Impact Crusher. The main objective is to design impact stone crusher. Impact stone crusher

Jaw Crusher Strong Stability and Humanization Design

9/8/2022· Jaw crusher as the “key crusher machine” in crushing production, whether it is a mineral processing production line or sand production line, jaw crusher is used everywhere. Luoyang Dahua JC jaw crusher not only has strong stability, but also is humanized design, can fully meet the production and use of customers under different conditions.

Jaw Crushers McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material. A toggle plate and tension rods

Jaw Crushers Parker Plant

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with

Jaw Crusher Design;jaw Crusher Stroke

Design of Jaw Crusher with power and stroke forces. Chapter 4. Jaw Crusher #2fishygirl on Scribd Scribd. Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate . In the return stroke, .

Jaw Crushers Armstrong Equipment

The new quick-change jaw die system and quick-adjust hydraulic shim system provide more uptime. Combine these features with our well-known durability and you have a crusher that keeps you up and running. Reliability, quality, capacity, and ease of use—the new ® Cedarapids JS Series jaw crushers are designed to help you be more profitable.

Designing a Crushing & Screening Plant Part I. Primary Jaw

27/10/2020· The simplest design of the jaw crusher stage is to feed all material directly into the jaw crusher from the dump hopper, see Figure 1. Figure 1. The simplest possible jaw crusher stage: Feeding all material from the dump hopper into the jaw crusher. This is not an efficient design though, since the feed contains a lot of fine and mid-size material that will not be

Diagram Jaw Crusher Crusher Mills, Cone Crusher, Jaw Crushers

“Computer Aided Design of Jaw crusher” 1.4 Schematic Diagram of a jaw crusher 8 2.1 Equivalent four bar mechanism diagram 13 2.2 Graph: Crank angle v/s angle black jaw crusher diagram process crusher. black jaw crusher diagram 1 Views. The liming is the professional mining equipments manufacturer in the world, located in China,India, along with

What Are Jaw Crushers and How Do They Work?

28/3/2019· March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who

(PDF) Design of Impact stone crusher machine

31/5/2019· Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher and Impact Crusher. The main objective is to design impact stone crusher. Impact stone crusher

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that