أرسل لنا رسالة

cyanide leaching acacia

Intensive cyanide Leach Hydrometallurgy: Leaching in Heap, Vat,

The intensive cyanide leach is smaller and more compact, but like any high intensity process subject to upsets from minor process changes. Acacia reactor + E.W have has proven to

Intensive Cyanidation Leach Optimisation Hydrometallurgy:

I think the main issue for the Acacia is when the amount of gold or sulphides in the concentrate varies widely day to day. I think your first action must be to increase cyanide addition until you

Cyanide Leaching SGS Colombia

Vats and Column Leach. In traditional cyanide leaching, ore is placed in vats or columns. The cyanide solution percolates through the ore and dissolves the gold, which is then removed

Consep Engineering Innovation

The Consep Acacia typically achieves overall recoveries in excess of 95%, often over 98%. Most importantly the Consep Acacia maintains an unblemished installation success rate. The plant

Cyanide Leaching Chemistry & Gold Cyanidation

The reactions that take place during the dissolution of gold in cyanide solutions under normal conditions have been fairly definitely established. Most agree that the overall cyanide equation

The Acacia Reactor Improving Gravity Recovery

While primary gravity recovery using centrifugal gravity concentrators, such as Knelsons, can be high, significant gold losses are realized in upgrading the gravity concentrates in the gold

The Metallurgy of Cyanide Gold Leaching An Introduction

A paper published by L. Elsner in 1846 first correctly identified the chemical reaction that forms the basis of all gold cyanide leaching processes: 4 Au + 8 NaCN + O 2 + 2 H 2 O → 4 Na [Au

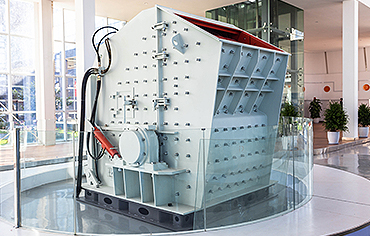

CONSEP ACACIA: THE FINEST IN LEACHING TECHNOLOGY GCA

The Acacia offers this in the safest, most cost effective and most efficient way possible. It uses an up flow fluidised reactor for the leaching process, to produce the ideal solid-liquid interaction.

Gravity Leaching With the ConSep ACACIA Reactor — Results

Gravity Leaching With the ConSep ACACIA Reactor — Results From AngloGold Union Reefs J Campbell1 and B Watson2 ABSTRACT The ConSep ACACIA Reactor is a device, which

Calculating Cyanide Consumption Mineral Processing & Metallurgy

Computing Cyanide Consumption of a laboratory leach test may be done as in the following example: Ore taken, 250 grams. Ratio of solution to ore, 3:1 = 750 cc: 250 grams. Cyanide

Gold Cyanide Leaching Process Metso Outotec

This makes cyanide detoxification a critical part of each cyanide leaching plant operation. Metso Outotec offers several process options for cyanide detoxification in addition to natural degradation or solution dilution. Cyanide detoxification by the SO₂ /air process is commonly used, but the most efficient detoxification method is selected based on individual process requirements.

5 Intensified Cyanide Leaching Methods You Need to Know

25/3/2021· 1. The concentration of CO 2 in the slurry is reduced. Thereby reducing the consumption of cyanide by CO 2; 2. Due to the use of pure oxygen, the leaching speed is greatly accelerated, thereby eliminating the effect of side reactions that consume cyanide; 3. Pure oxygen oxidizes some cyanide-consuming substances.

Gravity Leaching With the ConSep ACACIA Reactor Results From

The ConSep ACACIA Reactor performs a two-fold role. Firstly it increases gravity gold production, leading to a decreased CIP feed grade. Secondly, it removes slow leaching components from the plant leaching circuit. This two fold benefit leads to the following efficiencies: enhancement of the dissolution kinetics; enhancement of the adsorption

The Metallurgy of Cyanide Gold Leaching An Introduction

A paper published by L. Elsner in 1846 first correctly identified the chemical reaction that forms the basis of all gold cyanide leaching processes: 4 Au + 8 NaCN + O 2 + 2 H 2 O → 4 Na [Au (CN) 2] + 4 NaOH. The equation is well known, but the successful application of this reaction in a gold mining operation is rarely straightforward.

How Cyanide Leaching is Used in Gold Mining

3/7/2015· 1. Controlled Mills. This process which is also known as ‘vat leaching’ most often takes place in a specialized mill that is located on the mining premises. This process works by exposing the surface of the finely crushed ore to the cyanide salt solution. Once exposed to the gold, the solution binds with ions in the gold that allows them to

INTERNATIONAL CYANIDE MANAGEMENT INSTITUTE Summary

Acacia Bulyanhulu Gold Mine 22nd 26th June 2015 _____ Bulyanhulu Mine Signature of Lead Auditor 13th December 2015 Page 1 of 28 cyanide leaching reaction followed by electro-winning to produce doré bars. The primary cyclone overflow is sent to rougher flotation from where the tailings are thickened and disposed of to the tailings dam or as backfill. The rougher

Leaching Chemical (GDA) replacement of Cyanide LinkedIn

12/10/2015· The highest leaching rate of raw ore with residue GDA is 99.6%, Cyanide residue will be able to leach another 30-78%. Lower cost. It helps the enterprise to save the costs of transportation

INTERNATIONAL CYANIDE MANAGEMENT INSTITUTE Gold

an intense leaching (Acacia) system. In the hydrometallurgy plant, a concentrate of 90% passing 325 mesh is leached in a cyanide solution, adsorbed using activated carbon, stripped and fused into bars (bullion) containing gold, silver and impurities in the foundry. The Hydrometallurgy Plant 1 Introduction The Hydrometallurgy process is divided into two separate plants: Hydro I,

acacia intensive leach

The Acacia reactor was developed to maximize gold recovery in gravity concentration circuit using an intensive cyanide leaching process. Additional benefits observed with the use of the Acacia Reactor were: increased security, reduced gold grade reporting to the primary cyclone overflow, reduced gold content in the comminution circulating load

Acacia Reactor PDF Mill (Grinding) Gold Scribd

LEACHING GRAVITY CONCENTRATES Using the ACACIA REACTOR By W Lethlean Chief Metallurgical Engineer AngloGold Australasia And Laurie Smith Principal Laurie Smith and Associates C:\Temp\Randol paper.doc Page 2 Of 1111 The ACACIA Reactor 1 INTRODUCTION When coarse gold is present in an ore, there are advantages in physically recovering this gold

5 Intensified Cyanide Leaching Methods You Need to Know

25/3/2021· 1. The concentration of CO 2 in the slurry is reduced. Thereby reducing the consumption of cyanide by CO 2; 2. Due to the use of pure oxygen, the leaching speed is greatly accelerated, thereby eliminating the effect of side reactions that consume cyanide; 3. Pure oxygen oxidizes some cyanide-consuming substances.

The Metallurgy of Cyanide Gold Leaching An Introduction

A paper published by L. Elsner in 1846 first correctly identified the chemical reaction that forms the basis of all gold cyanide leaching processes: 4 Au + 8 NaCN + O 2 + 2 H 2 O → 4 Na [Au (CN) 2] + 4 NaOH. The equation is well known, but the successful application of this reaction in a gold mining operation is rarely straightforward.

Cyanide Use in Gold Mining Earthworks

A sodium cyanide solution is commonly used to leach gold from ore. There are two types of leaching: Heap leaching: In the open, cyanide solution is sprayed over huge heaps of crushed ore spread atop giant collection pads. The

Kinetic Investigation and Dissolution Behavior of

10/5/2019· The most commonly used cyanide salts are KCN and NaCN, which are easily soluble in water. Cyanide leaching is the dominating process for gold recovery from primary resources, due to its simplicity

Optimizing and evaluating the operational factors

8/12/2015· The influential factors investigated in the cyanide leaching process of gold included the solution pH, the solids percentage, the NaCN concentration, the particle size and the leaching time. The following conclusions can be

TREATMENT OF CYANIDE HEAP LEACHES AND TAILINGS ELAW

CYANIDE LEACHING Cyanidation uses solutions of sodium or potassium cyanide as lixiviants (leaching agents) to extract precious metals from ore. Cyanidation techniques used in the gold industry today include heap or valley fill leaching, agitation leaching followed by carbon-in-pulp (CIP), and agitated carbon-in-leach (CIL). Cyanidation is best suited to fine-grain gold in

Researchers find cyanide-free gold leaching process

12/1/2021· Staff reporter. As part of an eight-year study Curtin University researchers developed an improved glycine leaching technology that enhances the leaching rates for gold ore without using cyanide, a highly toxic chemical compound known to have detrimental effects on the environment and the human body. Typically when leaching gold with glycine

(PDF) Leaching of gold ores with high cyanicides: a

10/7/2018· Optimization of gold leaching and cyanide consumption requires a methodology to estimate the amount of exposed cyanicides, their leaching kinetics, and speciation of cyanide complexes that consume

Gold leaching in non-cyanide lixiviant systems: critical issues on

1/6/2004· Recently, cyanide leaching has been progressively inhibited by environmental pollution and long processes. In this study, the effect of leaching conditions on the extraction of gold was investigated with the new environmentally friendly gold lixiviant “Jinchan” (JC) as a substitute for cyanide. The extraction of gold is 90.8% under the optimum parameters as the

Gold Processing Options

commercial operations in what are considered to be first world countries. These are cyanide leaching and flotation. 2. CYANIDE LEACHING Currently within the gold mining industry, cyanide (CN) is the most commonly used chemical in the economic recovery of gold. Cyanide has been utilised for over 100 years. Approximately 1.1 million tonnes of